|

China Bearing Products Directory

|

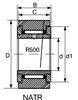

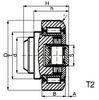

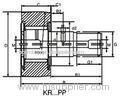

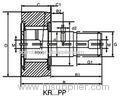

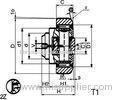

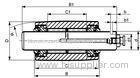

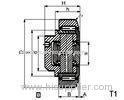

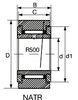

Bearings for Material Handling System: Support Rollers NATV25 | NATV25PP

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Bearings for Material Handling System

Bearings for Material Handling System Track roller bearings can withdraw heavy load rating and sho

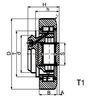

Bearings for Material Handling System Track roller bearings can withdraw heavy load rating and shock load rating by their thick outer race. They are ready-to-fit units and are intended for all types of cam drives, tracks, conveyors, material handling systems and so on.

According to customer's application, the OD surface can be designed to be flat , crowned and other special ones. Cam rollers with crowned runner surfaces should always be used where angular misalignments with respect to the track expected and edge stresses kept to a minimum.

Track roller bearings are based on ball bearings, needle roller bearings as well as cylindrical roller bearings. Because of the wide variety of designs they are suitable for the most diverse operating conditions.

Tolerances:

WD track roller bearings are produced according to Normal tolerance P0 standard, except for the tolerance of the crowned runner surface diameter.The values for tolerances tally with ISO 492.

Clearance?

C2, C0, C3, C4, C5 radial internal clearance are available and also special radial internal clearance is available as customer's application providing the clearance limits are as specified in ISO 5753.

Load rating?

Dynamic load rating conform to ISO281/1 and static load rating conform to ISO76.

Lubrication ?

The track roller bearings, filled with lithium grease, have a good anti-rust capability and can work among the temperature range from-30?to+120?. Generally speaking, they are greased for life and are maintenance-free under normal working condition. However, if they are subjected to moisture or solid contaminants, or if they keep runing for a long periods under temperatures above 70?, they should be relubricated with same grease by the oil hole in the inner race or other lubrication method. High and low temperature grease are also available according to customer's request.

The WD track roller bearings consist of:

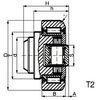

? Combined bearings

? Cam followers

? Mast rollers and chain pulleys

? Cam roller bearings

? Supporting rollers

? Other non-standard rollers

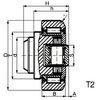

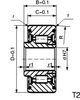

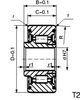

WD support rollers are basically needles or cylindrical roller bearings with a thick-walled outer race. The rollers are available either with a flat runner surface or crowned runner surface, which can be designed according to customer's application.

With this outer race, the support rollers are able to roll directly in the raceway and bear a heavy load rating. The crowned runner surface should always be used where angular misalignments with respect to the track expected and edge stresses kept to a minimum. They are ready-to-fit units, filled with grease and are suitable for all types of cam drives, tracks, conveyor systems and etc.

The support rollers can be divided into ones with axial guidance or without axial guidance. And from sealing structure, they can be divided into open type and sealed type.

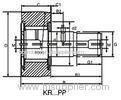

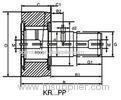

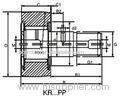

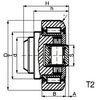

| Shaft Diameter mm | 52 |

| Without Seal | NATV25 |

| Massg | 285 |

| Sealed | NATV25PP |

| Massg | 285 |

| dmm | 25 |

| Dmm | 52 |

| Bmm | 25 |

| Cmm | 24 |

| D1mm | 42 |

| Cr Dynamic N | 29000 |

| Cor Static N | 69600 |

| Grease rpm | 2100 |